Conveyor System

400USD-600USD/m

In the configuration of the conveyor line, it must be taken into account that when the equipment in the rear section is temporarily shut down (such as changing labels, etc.), it will not affect the operation of the equipment in the front section to achieve higher operating efficiency.

Modular Mesh Belt Conveyor

This belt conveyor is a revolution to the traditional belt conveyor. It overcomes the difficulty of belt conveyor maintenance and the shortcomings of the belt being easily torn, punctured and corroded, and provides customers with a safe, fast and easy maintenance. Simple delivery method. Because this type of conveyor uses a modular conveyor belt, and the transmission method is driven by a sprocket, the conveyor belt is not easy to snake and deflect.

Because the belt is thick, it can withstand cutting, collision, and oil and water resistance. When used in the industry, there will be no troubles in maintenance, especially in the replacement of conveyor belts, which will reduce an expense.

Roller Conveyor

Industrial roller conveyor systems without power/manual roller conveyor are applicable to transport the goods whose bottom is flat. For example: electronic, beverage, food, packaging, machinery, electronics, light industry, tobacco, chemical, pharmaceutical, rubber, motor cycle, logistics etc. Manual roller conveyor relies on operating goods or rely on gravity slide transport at a certain tilt angle.

Features

1. Body material: The whole body is made of carbon steel plate, and the surface is sprayed with plastic;

2. Tripod: It is made of 40*40*2.0t carbon steel square tube welded, and the surface is sprayed with plastic;

3. Turning roller: black tapered PVC double chain roller

4. Straight roller: φ50 double chain roller, stainless steel barrel, wall thickness 1.5mm, shaft center is made of carbon steel

5. Motor: Taiwan brand

6. Chain: 08B carbon steel chain

7. Guardrail: big C aluminum rail guardrail

8. Foot hoof: It is composed of M16 galvanized screw rod and φ100mm plastic foot plate.

Belt Conveyor(plastic/Stainless)

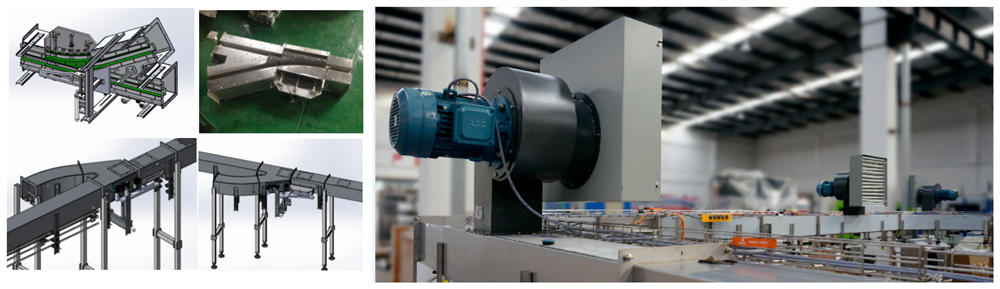

The filled bottle conveyor line is composed of a number of conveyor units, which can be connected in accordance with the actual requirements.

It mainly contains a basic transport unit, no-pressure transmission unit, bottle temporary storage station, etc.

Our belt conveyor includes the option for the separate cabinet, each motor speed can be individually controlled and lubricate system.

Features

1.No pressure conveying system can be divided into two suites: the first is the section for single-to-multi and multi-to-single lines on the capper entrance; the second suit is the section on the entrance of the labeling machine (single-to-multi and multi-to-single lines).

2.The magnetic suction or corner chain is applied to the corner conveyor.

Stable conveying: bottles are smoothly transferred on the single-lined chain plate without any crush or collapse.

3.The electronic control components are imported, such as SIEMENS, SCHNEIDER, MITSUBISHI, etc. with signals on the labeling machine.

4.Programming control and speed-adjustable frequency conversion motor are adapted for the simultaneous speed between conveying and mainframe.

5.The bottle-flow-check switch automatically pauses motor operation in accordance with the signal.

Power | AC 220V/sph、 AC 330V/sph | |

Output (KW) | 0.25、0.37、0.55、0.75、1.0 Gear Motor | |

| Frame Material | AL、CS、SUS |

Chain Material | POM、SUS | |

| Chain type | Tabletop chain, Anti-slip chain, SUS chain, etc |

Chain width W2 (mm) | 63.5、82.6、114.3、152.4、190.5、254、304.8 | |

Applicable bottle | 10ml-10L | |

| Conveyor Width W (mm) | 90-500 (Other to be customized) |

Conveyor Length L (mm) | ≤30000 | |

Conveyor Height H (mm) | 700 (Other to be customized) | |

| Speed (m/min) | ≤45 |

Load (kg) | ≤50 (Horizontal)、≤25 (Vertical) | |

Working tension (N) | ≤1250 | |

Working temperature (℃) | -20~+60 | |

Radius (mm) | ≥610 | |

Accessories | Side plate, Roller plate, Nylon plate | |

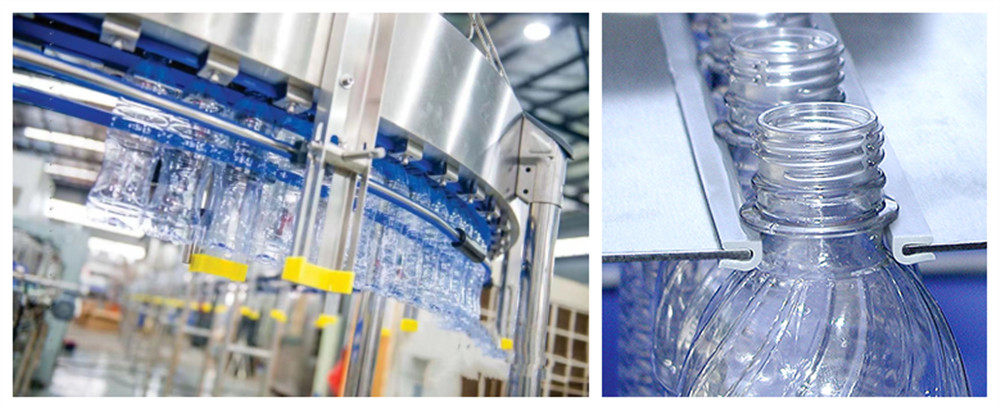

1. Adopting airflow transmits theory with air filter make sure the air is clean to touch the bottle neck.

2. Greatly reduce floor space due to overhead cradle installation, increase usage rates of plant.

3. Bottle hold bar adjustable automatically, apply to various of bottles.

4. Adopting frequency speed regulation and air blowing rate regulate devices to adjust airflow supply speed. Guarantee PET bottle be conveyed uniformly to avoid impaction.

5. Split-flow,confluence,displacer(two to two)all be controlled automatically (bottle gripper device installed in air duct), accomplish path (air pipe)option. And also, can implement camera remote monitoring.

6. Bottle gripper made of high polymer material to prevent bottle abrasion.

7. Whole course monitored by Photo electricity sensor, go up and down, change frequent automatically, bring down energy cost, also can judge PET transmit in block situation and solved the problem automatically by cylinder patting PET bottle.

Applicable Bottle | PET Bottle(plastic bottle) |

Frame Material | Stainless Steel 304 |

Capacity | 1000-48000BPH |

Size and weight of transport | Semidiameter of bend swerve 1200mm |

Applicable bottle size | Neck size 25mm~38mm |

Energy consumption | Power 1kw-2.2KW |

Dimensions | Size of section 200×220mm |

Machine volume | Customized |

苏公网安备 32058202010956号

苏公网安备 32058202010956号